quick links

Office Hours

Mon 8am – 10pm

Tues 8am – 10pm

Wed 8am – 10pm

Thur 8am – 10pm

Fri 8am – 10pm

Sat 8am – 10pm

Sun 8am – 10pm

Office Address

Service Areas

Affordable Insulators, a trusted name in the insulation services business, provides a comprehensive spectrum of polyurethane concrete leveling & raising and maintenance services to suit diverse needs and budget. Whether you need concrete raising, void filling, or slab stabilization, we are ideally placed to address various concrete related issues, saving you from incurring prohibitive replacement costs.

Our experts conduct an in-depth assessment to determine whether your structure needs leveling and repair, or a complete replacement. Based on the findings, we offer professional and unbiased advice on the best way forward. Since inception, all of our clients have been pleasantly surprised at the savings they have been able to realize through our expert services, and you could be the next.

Polyurethane concrete leveling & raising is an effective alternative to replacement, entailing savings of up to 50 percent. Apart from being a reliable and cost-effective solution, polyurethane concrete rising allows the work area to sustain normal usage within a few minutes after the completion of the job. In addition, easy material processing and clean up make it an obvious choice over mud-jacking.

Polyurethane foam treatments are not only a viable solution for sunken concrete surfaces, but can also be used for void filling and stabilization in an array of structures such as patios, front porches, driveways, sidewalks, garage & parking slabs, steps, and pool decks, among others. In all cases, the process promises exceptional savings, without affecting the day-to-day activities in the area.

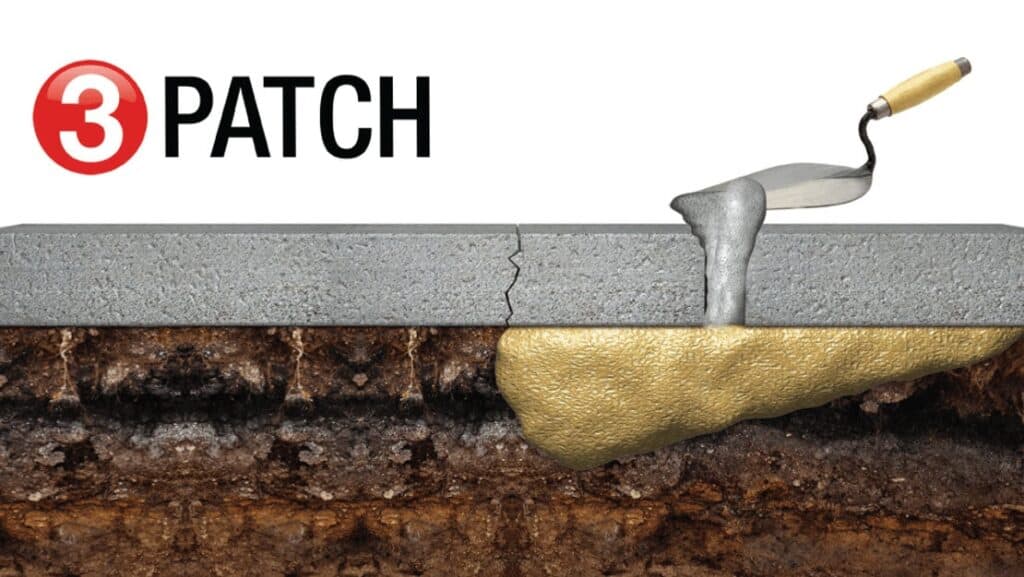

Most concrete raising jobs take approximately 1-2 hours to complete, after which it is ready for normal usage almost immediately. Here’s an overview of how it works:

High-Density Polyurethane Injection is used for concrete lifting, stabilization, and void filling applications. Preferred by Contractors and DOTs around the USA. Lifting concrete with foam offers the same results of traditional concrete leveling & raising, stabilization, and void filling, but with new and improved characteristics. Cost-effective compared to concrete replacement, this high-density polyurethane foam has quick cure time, is hydrophobic, moisture barrier, lightweight and provides 5/8” injection holes. With a material for any application, we are leading the concrete leveling & raising industry with this revolutionary new polyurethane application.

Cost-effective Concrete Raising

Cost-effective Concrete RaisingDensity Polyurethane concrete lifting and stabilization avoid costly tear out and replacement. This allows business to run smoothly around the Polyurethane project avoiding down time.

Polyurethane typically cures 15 minutes after injection allowing areas to be fully available in minutes not days.

Specially designed High-Density Polyurethane can be used in underwater or wet applications and have the same chemical reaction.

Because of high-density polyurethane characteristics, this foam-like material is resistant to water penetration.

Spray Polyurethane Foam (SPF) is an insulation product that is spray-applied in situ at a building site or residence. Two liquid components, MDI (A) and polyol blend (B) are mixed under pressure and sprayed onto a roof or wall cavity. The reacting liquids expand and solidify into a foam matrix creating a seamless seal. SPF adheres well to the area it is applied to, providing an air barrier that prevents thermal leaks.

Closed-cell foam (sometimes known as two-pound or medium density foam) has a high R-value of around 6 per inch. It acts as an air and vapor barrier. It also provides structural enhancement.

Open-cell foam (sometimes known as half-pound or low density foam) has an R-value of 3.6 per inch, and may act as an air barrier. It also acts as a noise absorber.

SPF provides insulation, air and moisture protection for many different commercial building roof and wall configurations. SPF use allows for flexibility of building design, reducing overall maintenance costs, and can extend the lifespan of the building.

SPF seals wall and roof cavities to save the homeowner money on heating and cooling expenses. Not only does it provide thermal protection, it provides moisture and air barriers mitigating dangerous mold and wood rot of the structure.

Mon 8am – 10pm

Tues 8am – 10pm

Wed 8am – 10pm

Thur 8am – 10pm

Fri 8am – 10pm

Sat 8am – 10pm

Sun 8am – 10pm